Click Here for finish details.

Finishes

Poli-5000 Powder Coat – The most durable powder coat finish system in the industry. Steel is shot blasted to a near white condition, given a phosphate wash, coated with an epoxy primer, and then followed with a coat of polyester TGIC powder formulated for maximum UV protection, adhesion, and fade resistance. The Poligon Poli-5000 process is a completely in-house system and is available in a wide range of smooth, textured, and metallic colors.

Additional benefits include:

- Higher surface hardness/scratch resistance than common liquid coatings

- Reduced chance of damage to coating during installation

- High resistance to cleaners and chemicals

- High resistance to wind-borne abrasives

- Certified by the Powder Coating Institute as PCI-4000

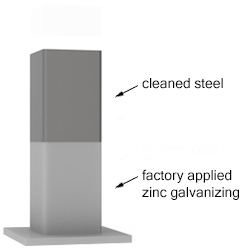

Galvanized – A basic, long-accepted method of protecting steel from corrosion, galvanizing is the process of coating steel with zinc using a hot bath process. Galvanizing is considered the best corrosion protection process available for steel components and is commonly used where exposure to salt air is anticipated. The galvanizing process results in a random, spangled finish that can also have alternating areas of haze and sheen.

Additional benefits include:

- The zinc finish causes a cathodic process, protecting the steel substrate

- The zinc corrodes very slowly giving long lasting protection

- The complete dip coverage of zinc gives 100% protection of steel components

- Extremely durable, with little or no maintenance required

- The best and toughest protection available